Nickel S-Pellets™

Nickel S-Pellets™ are a high purity form of sulphur-activated nickel widely used for electroplating with titanium anode baskets. S-Pellets™ are produced by a unique carbonyl gas refining process at the Clydach Nickel Refinery in the UK.

The controlled and consistent purity of S-Pellets™ and the advantages associated with its distinctive shape and sulphur activation make this product attractive for high-end plating (e.g. high-speed engineering, electronics, electroforming) with titanium anode baskets:

- Carbonyl refining produces the purest form of nickel available

- Sulfur activation promotes uniform dissolution and low operating voltage, even in chloride-free plating baths

- Unique shape prevents the formation of bridges and voids in the basket

- Settles uniformly in basket, ensuring uniform current density and high quality deposits

- Flows easily into regular and shaped baskets with standard mesh sizes

- Ideal for use with automated basket loading devices

- Safe to handle (no sharp edges)

- Dissolves at 100% anode efficiency in common nickel plating solutions – with or without chlorides

- Dissolution produces minimal metallic residues

The sulphur in this product does not enter the plating solution; it forms an insoluble nickel sulphide residue, which is 100% contained using cloth anode bags, where it acts to remove unwanted copper impurities.

S-Pellets™ are produced in compliance with the following standards: ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007.

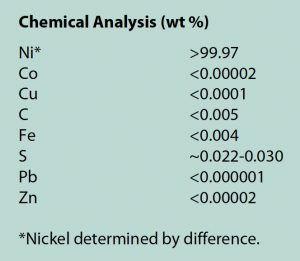

Typical Specifications

Form

- Spherical pieces of nickel

- Diameter: approximately 6 – 14 mm

Packing Density

- Approximately 5.4 g/cm3 of basket capacity

Packaging

- 10 kg bags, 5 bags per box, 20 boxes per pallet (1,000 kg net weight)

- 1 tonne bulk bags